Nowadays, innovative technologies go hand-in-hand

Offset printing•

Offset printing is one of many printing technologies available. It is a type of flat printing in which the image is transferred from a flat plate to the substrate (paper, cartons, film-coated cartons) via an intermediate cylinder covered with a rubber blanket.

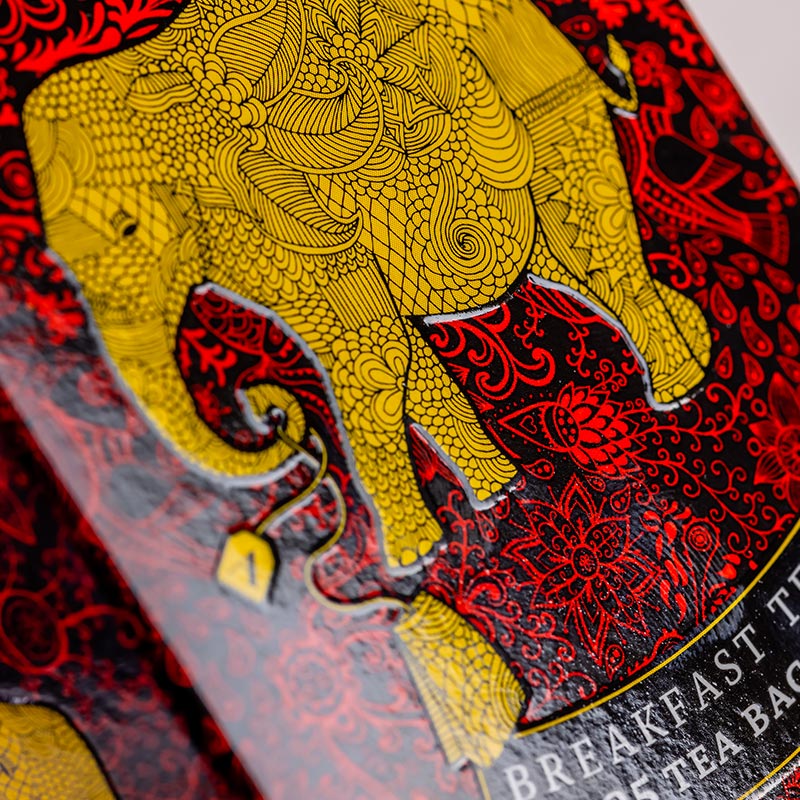

In the printing process, applying different finishing to the printed substrate such as the application of a metallic layer (cold foil) and varnish not only protects the surface, but also gives it a high-quality appearance.

Offset printing use various drying systems which are applied depending on the printed substrate absorption rate and further processing required (e.g. the amount of printing ink). The technologies used include:

Conventional – drying with infrared light.

UV – drying with high-energy ultraviolet light.

LED UV – drying with low-energy ultraviolet light.

Varnish•

Coating the printed cardboard surface usually takes place during the offset printing process, and this results not only in a mechanical protection against ink abrasion, but also eye-catching visual effects (such as changes in print colour or surface properties).

Coating is usually completed with dispersion and UV varnish, which can result in a glossy or matte appearance, and can cover the entire packaging surface or selected parts (spot varnish).

Remarkable effects can be achieved by combining matte and glossy varnish (hybrid coating).

Contact us•

Tell us about your project and we will come back to you with a proposal for implementation.

Address

DOT2DOT SA

Headquarters

7R PARK GDAŃSK II, ul. Magnacka 35

80-180 Kowale, Poland

![]()

Tel: (+48) 600 374 984

Tel: (+48) 607 602 922

![]()