Window patching•

Window patching is ideal for luxury products or gift sets. This solution allows the contents of the packaging to be perfectly visible to the consumer.

The windows can be made in almost any possible shape. They can be printed or unprinted, placed on one side of the package or on the corner.

We are among only a few in the industry who can produce creased windows. This solution makes the product inside the package visible from more than one viewing point.

We offer solutions that are optimal in shape and size to highlight the uniqueness of the contents.

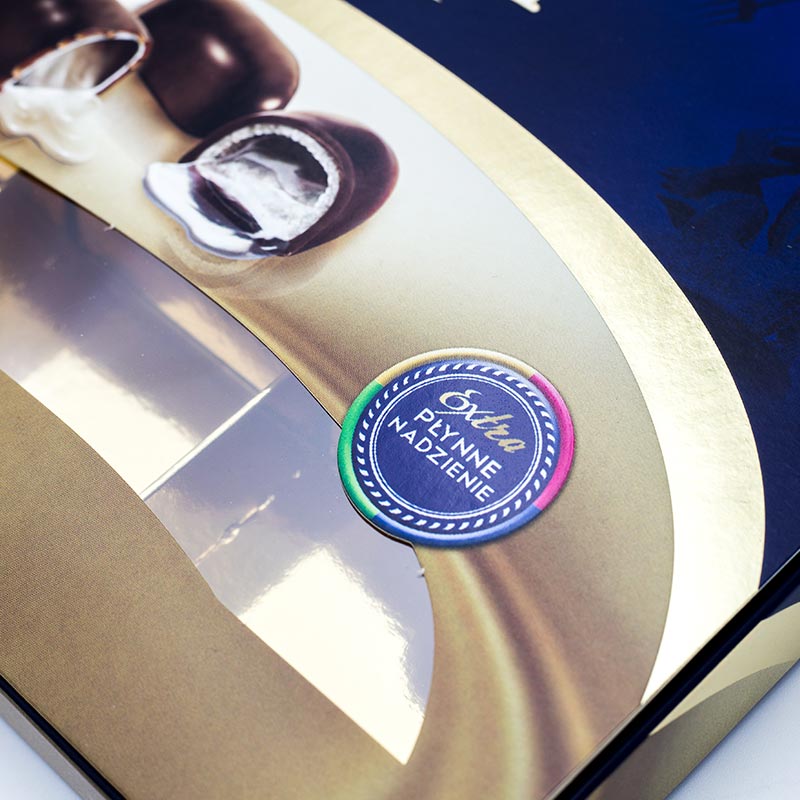

Die cutting•

Die cutting is the process of cutting a desired shape from cardboard or corrugated board. It also involves modifying the substrate to properly form the packaging.

During die cutting, embossing, i.e. pressing a three-dimensional pattern into the substrate, is also possible. Such embossing can be done on all types of packaging.

The die-cutting process is done using:

- a die cutter with appropriately shaped cutting knives

- creasing rules for making creasing lines for easier folding and packaging forming

- knives which score the substrate but do not cut through it (for easier package folding)

Litho lamination•

The litho lamination process is used when manufacturing packaging made of corrugated or solid cardboard. It was developed for processing corrugated cardboard, which – due to high pressure – cannot be printed using offset technology.

What does the process look like?

Litho lamination consists of sealing a thick substrate (corrugated cardboard) with a thinner paper (liner), which is already printed and coated. The two layers are combined with a water-based adhesive.

This technology is primarily used in the production of packaging where durability is required due to the weight of the product, especially for carton boxes made for liquors, household chemicals or food.

Most importantly, packaging produced using litho lamination technology with printed and decorated liner combines visual effects with an exceptional mechanical strength which is perfect for corrugated cardboard. Precise printing process, available finishing types (e.g. cold foil, hot stamping, matte/gloss foil) and accurate registration in the litho-lamination process, makes it possible to achieve the same high quality of printing and finishing as unit packaging.

Gluing•

Multipoint gluing can be used in the production of all types of packaging, both made of cardboard and corrugated cardboard (litho-laminated).

Depending on the packaging design and the material used, various types of cold and hot-melt glue are used in multipoint gluing.

We are one of only a few companies on the market with gluing lines enabling complex gluing constructions of up to 8 glue points.

Line gluing is the most common process in the production of simple cardboard packaging and used less frequently for laminated or litho-laminated cardboard packaging. Cold glue is usually used in line gluing. Other types of gluing are used for packaging made on metallised or litho-laminated substrates.

Contact us•

Tell us about your project and we will come back to you with a proposal for implementation.

Address

DOT2DOT SA

Headquarters

7R PARK GDAŃSK II, ul. Magnacka 35

80-180 Kowale, Poland

![]()

Tel: (+48) 600 374 984

Tel: (+48) 607 602 922

![]()