Plastic

to Paper

We support customers in creating a more sustainable, plastic-free packaging.

We make sustainable premium quality packaging from scratch. From construction design to the final product, you are always in good hands.

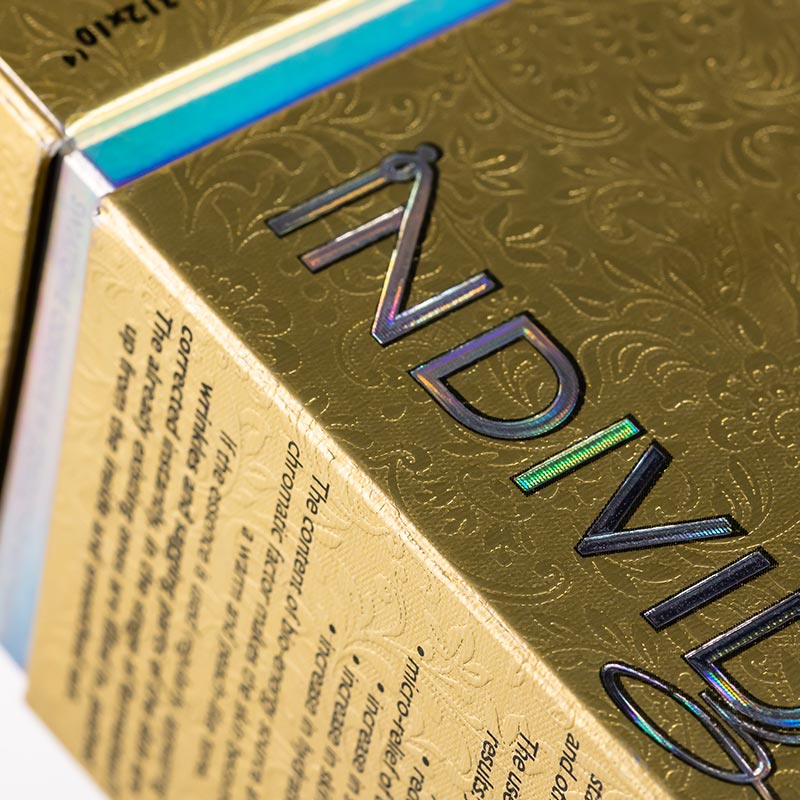

We offer all finishing types you can probably think of! Offset print, lamination, cold foil, hot stamping or our innovative eco-friendly ECOLURE technology to name a few.

Find out what we can do for you!

billion units produced annually

standards

standards

The welfare of our customers, partners and employees is our top priority. Not just here and now, but in the years to come. We want the future generations to have the chance to experience a clean and beautiful world. This is why at DOT2DOT, we have made it our goal to make all of the activities we undertake as sustainable as possible.

We understand that sustainability and the circular economy have become key issues in every nation’s economy, and that compliance with sustainability regulations is now an obligation of every packaging manufacturer. Our investments in new eco-technologies enable us to keep up with market expectations and to offer more ecological packaging solutions.

In each of our production facilities we use an array of technologies to achieve stunning effects on paper

Offset printing is one of many printing technologies available. It is a type of flat printing in which the image is transferred from a flat plate to the substrate (paper, cartons, film-coated cartons) via an intermediate cylinder covered with a rubber blanket.

Coating the printed cardboard surface usually takes place during the offset printing process, and this results not only in a mechanical protection against ink abrasion, but also eye-catching visual effects (such as changes in print colour or surface properties).

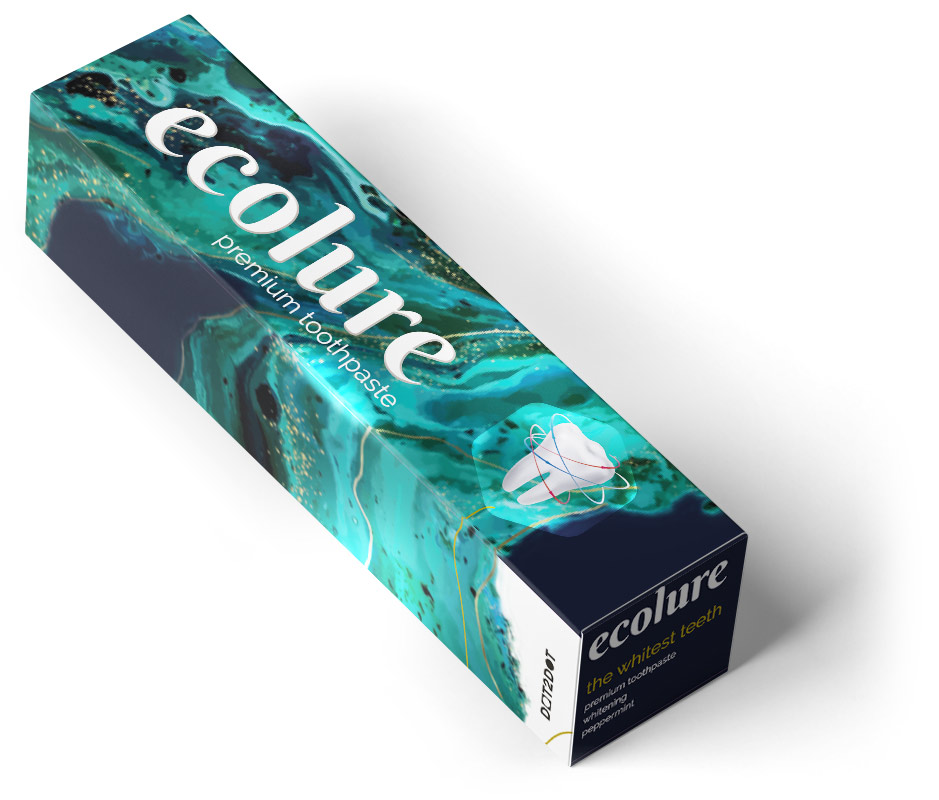

Innovative eco-friendly technology developed by the DOT2DOT team – biodegradable and recyclable metallised packaging without PET film. An environmentally friendly alternative to the traditional lamination method using PET film.

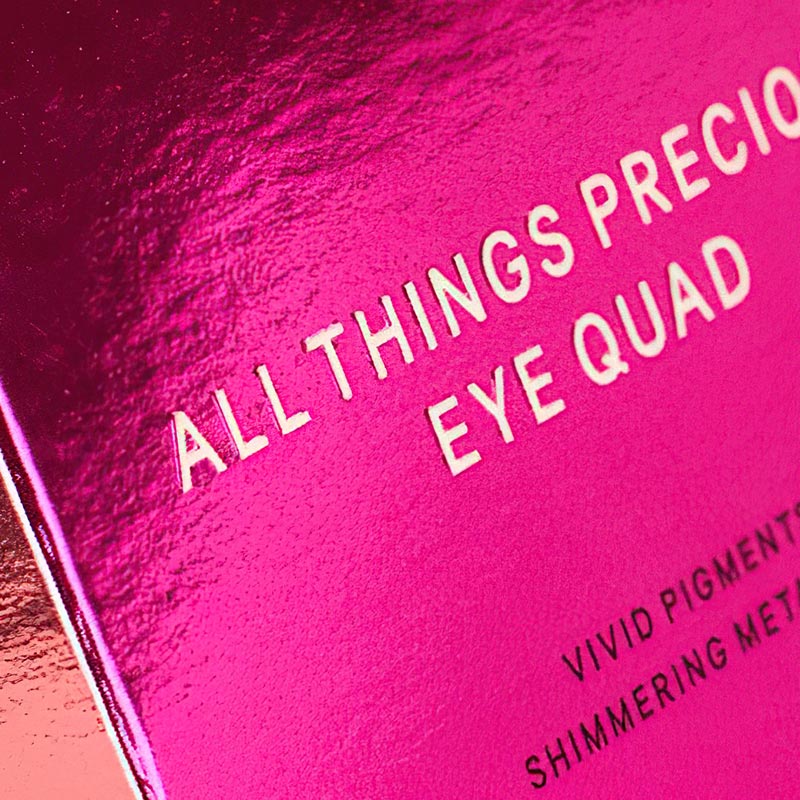

Conventional laminating (in the “cold” or “hot” process) is a technology in which the entire surface of a sheet is covered with a layer of PET film to create an attractive metallic coating. The substrate for lamination can be printed or unprinted, depending on the type of product and the desired effect, e.g. laminated trays for food or premium packaging.

Cold foil, or cold stamping, is a method of transferring a metallic layer onto the cardboard in the so-called “cold” foil printing process.

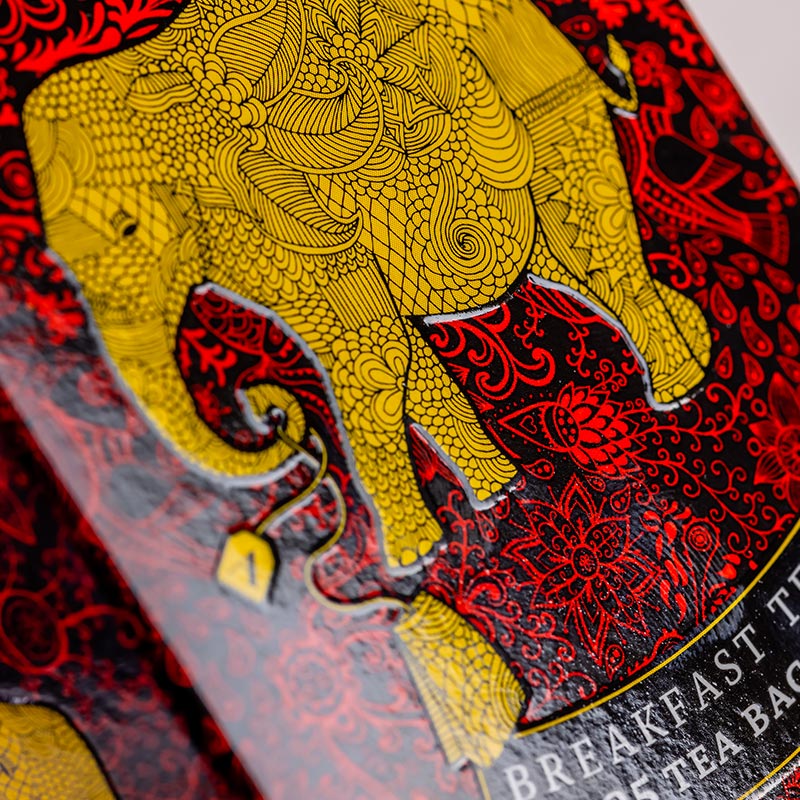

Hot stamping is a surface decoration method using high temperatures that results in a shiny metallic effect.

Soft touch is a packaging finish that makes the surface feel silky and velvety. This technology can be applied on almost any printed product.

The hybrid effect, also known as “drip off”, is achieved by simultaneously applying two visually different varnish types that result in a spot gloss and matte overlay.

Embossing is a process of creating patterns on cardboard with a 2D or 3D effect.

Special tools are used to create a high relief, debossing or a 3D effect, Braille text embossing, or the so-called dry embossing, with a delicate effect.

The litho lamination process is used when manufacturing packaging made of corrugated or solid cardboard. It was developed for processing corrugated cardboard, which – due to high pressure – cannot be printed using offset technology.

Die cutting is the process of cutting a desired shape from cardboard or corrugated board. It also involves modifying the substrate to properly form the packaging.

During die cutting, embossing, i.e. pressing a three-dimensional pattern into the substrate, is also possible. Such embossing can be done on all types of packaging.

Window patching is ideal for luxury products or gift sets. This solution allows the contents of the packaging to be perfectly visible to the consumer.

The windows can be made in almost any possible shape. They can be printed or unprinted, placed on one side of the package or on the corner.

Line and multi-point gluing are the most commonly used types of bonding in the production of cardboard packaging. The choice of the type of bonding and glue (cold or hot) depends on the type of cardboard or cardboard.

Discover the latest news and articles!

Tell us about your project and we will come back to you with a proposal for implementation.

DOT2DOT SA

Headquarters

7R PARK GDAŃSK II, ul. Magnacka 35

80-180 Kowale, Poland

![]()

Tel: (+48) 600 374 984

Tel: (+48) 607 602 922

![]()